|

|

|

SWT’s Tech Series High Flow Residential Water Softeners utilize ProSoft™ resin. This is the same resin SWT used to treat the water servicing the Capitol Building in Washington DC! These units include the newest in computer monitoring technology for maximized efficiency. Plus, these systems feature SWT’s revolutionary Cyclonic Distributor System™ to provide full bed contact, less channeling, and superior backwashing.

| • |

100% corrosion free system with stylish all black components |

| • |

Energy efficient controller uses less than $5.00 of electricity per year |

| • |

Never lose system memory and timer clock to power failure

— no battery required for backup! |

| • |

Water usage stored in memory |

| • |

Automatic variable reserve based on water usage history |

| • |

All units include upper screen, brine safety float, brine well overflow connection, brine tank with injection molded lid, brine line tube and connectors |

| • |

10 year warranty on tank, 5 year warranty on valve |

| • |

All components NSF listed |

| • |

All international voltages available |

|

|

| |

| Computer Metered Systems with Professional Level Programming |

| Part Number |

Tank

Size

Inches |

Softening Capacity *

Grains / Lbs of Salt |

System Service

Flow Rate |

Max. Valve

Flow Rate

@15 psid |

Standard **

Connection

Size |

6 lbs

Per

cu.ft. |

10 lbs

Per

cu.ft. |

15 lbs

Per

cu.ft. |

Standard |

Peak |

| WSCCDM125-100 |

9 x 48 |

23,800 |

30,200 |

34,400 |

5 GPM |

10 GPM |

34 GPM |

1.25 inch Brass Sweat |

| WSCCDM125-150 |

10 x 54 |

35,700 |

45,300 |

51,600 |

7.5 GPM |

15 GPM |

34 GPM |

1.25 inch Brass Sweat |

| WSCCDM125-200 |

12 x 52 |

47,600 |

60,400 |

68,800 |

10 GPM |

20 GPM |

34 GPM |

1.25 inch Brass Sweat |

| WSCCDM125-250 |

13 x 54 |

59,500 |

75,500 |

86,000 |

12.5 GPM |

25 GPM |

34 GPM |

1.25 inch Brass Sweat |

| WSCCDM125-300 |

13 x 65 |

71,400 |

90,600 |

103,200 |

15 GPM |

30 GPM |

34 GPM |

1.25 inch Brass Sweat |

| WSCCDM125-350 |

14 x 65 |

83,300 |

105,700 |

120,400 |

17.5 GPM |

34 GPM |

34 GPM |

1.25 inch Brass Sweat |

| WSCCDM125-400 |

16 x 65 |

95,200 |

120,800 |

137,600 |

20 GPM |

34 GPM |

34 GPM |

1.25 inch Brass Sweat |

| WSCCDM125-500 |

18 x 65 |

119,000 |

151,000 |

172,000 |

25 GPM |

34 GPM |

34 GPM |

1.25 inch Brass Sweat |

| WSCCDM125-700 |

21 x 62 |

166,600 |

211,400 |

240,800 |

34 GPM |

34 GPM |

34 GPM |

1.25 inch Brass Sweat |

|

| * |

Operating capacities based on influent of 400 ppm as CaCO3 with a ratio of 2 parts calcium to 1 part magnesium at 2.0 gpm/cu.ft. flow rate. Capacities include 10% safety factor. |

| ** |

Standard connection fitting is 1.25 & 1.5 inch Lead-Free Brass Sweat Assembly (P/N LC-V3007-09LF).

See below for other available fittings. |

| |

Operating Pressure: 20 to 120 psi

Operating Water Temperature: 35 to 100°F |

| |

Valve Service Cv = 8.8 |

|

| |

| |

| Additional Equipment: |

| |

|

| BYPASS VALVE |

| LC-V3006 |

Bypass Valve |

| |

|

| TANK JACKETS |

| RG-TJ0948EC |

Chrome Tank Jacket, 9 x 48 inch |

| RG-TJ1054EC |

Chrome Tank Jacket, 10 x 54 inch |

| RG-TJ1252EC |

Chrome Tank Jacket, 12 x 52 inch |

| |

|

| WEATHER COVERS |

| LC-V3175WC-W |

White Weather Cover |

| LC-V3175WC-A |

Almond Weather Cover |

| |

|

|

|

| LC-V3070FF |

No Hard Water Bypass Valve, Female x Female |

| LC-V3070FM |

No Hard Water Bypass Valve, Female x Male |

| LC-V3022 |

1 inch Stack Puller |

| LC-V3022-15 |

1.25/1.5 inch Stack Puller |

| LC-V3193-02 |

Service Spanner Wrench |

| |

|

| TECH SERIES AC ADAPTERS (TRANSFOMERS) |

| LC-V3186-05 |

AC Adapter (Transformer) 15V DC (North America Indoor) — STANDARD |

| LC-V3186-OD |

AC Adapter (Transformer) 110V-12V (North America Outdoor) |

| LC-V3186AUS-05 |

AC Adapter (Transformer) 15V DC (Australia Indoor) |

| LC-V3186AUS-OD |

AC Adapter (Transformer) 240V-12V (Australia Outdoor) |

| LC-V3186EU-05 |

AC Adapter (Transformer) 15V DC (Europe Indoor) |

| LC-V3186EU-OD |

AC Adapter (Transformer) 240V-12V (Europe Outdoor) |

| LC-V3186UK-05 |

AC Adapter (Transformer) 15V DC (UK Indoor) |

|

| |

| Grid plates, safety floats in brine tank, and alternate packaging for individual shipment also available. |

| |

| |

|

| Substitutions by Request: |

| |

|

| BRINE TANKS |

| LC-BT1833BLK |

Brine Tank, 18 x 33 inch, Black |

| LC-BT151733BLK |

Brine Tank, 18 x 40 inch, Black |

|

|

| FITTINGS |

Click to view all Tech Series Fitting Kits listed below. |

| LC-V3007 |

1 inch PVC Male NPT Elbow Assembly |

| LC-V3007-01 |

3/4 x 1 inch PVC Solvent Elbow Assembly |

| LC-V3007-02LF |

1 inch Brass Sweat Assembly (Lead Free) |

| LC-V3007-03LF |

3/4 inch Brass Sweat Assembly (Lead Free) |

| LC-V3007-04 |

1 inch Plastic Male NPT Assembly |

| LC-V3007-05 |

1.25 inch Plastic Male NPT Assembly |

| LC-V3007-06 |

1 inch Plastic Male BSPT Assembly |

| LC-V3007-07 |

1.25 & 1.5 inch PVC Solvent Assembly |

| LC-V3007-08 |

1.25 inch Plastic Male BSPT Assembly |

| LC-V3007-09LF |

1.25 & 1.5 inch Brass Sweat Assembly (Lead Free) — STANDARD |

| LC-V3007-12LF |

3/4 inch SharkBite® Assembly (Lead Free) |

| LC-V3007-13LF |

1 inch SharkBite® Assembly (Lead Free) |

| LC-V3007-14 |

3/4 inch Plastic Male BSPT Assembly |

| LC-V3007-15 |

3/4 inch John Guest® Elbow Assembly |

| LC-V3007-16 |

1 inch PVC Male BSPT Elbow Assembly |

| LC-V3007-17 |

1 inch John Guest® Straight Assembly |

| LC-V3007-18 |

3/4 inch Plastic Male NPT Assembly |

| LC-V3007-19 |

3/4 inch John Guest® Straight Assembly |

| LC-V3007-20 |

1 inch John Guest® Elbow Assembly |

| LC-V3191-01 |

Vertical 90 degree Adapter Assembly |

|

| |

| |

| NOTES: |

| A black 15 x 17 x 33 inch brine tank (P/N LC-BT151733BLK) with injection molded lid is standard with all units. Substitutions are available on request (see above). |

| 1.25 inch brass sweat installation fittings are standard. Substitutions are available on request (see above). |

| All units are supplied with ProSoft™ Premium 8% crosslink resin. Resin substitutions are available on request at extra cost. |

| Resin ratings are as follows: |

|

|

| In basic terms, crosslinkage refers to the resin beads’ physical strength or ability to withstand chemical attack from chlorine, resin bed cleaners, and caustics used in DI applications. |

| |

| |

|

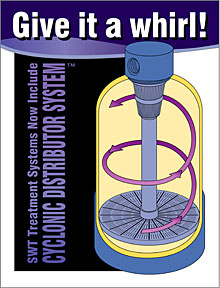

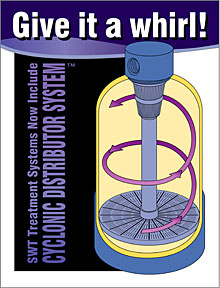

| SWT Systems Include the REVOLUTIONARY |

| CYCLONIC DISTRIBUTOR SYSTEM™ |

|

| • |

Up to 30% less backwash flow rate is required...conserving water for the customer |

| • |

Distributor plate is designed for more than 6,500 lbs load capacity |

| • |

Reduces system pressure loss while increasing flow and efficiency through the bed |

| • |

Bottom plate distributor (shown left) available for 7, 8, 9, 10, 12, 13, 14, and 16 inch diameter tanks |

| • |

Mid plate distributors (up to 4 per tank) available for 10 inch and 13 inch diameter tanks |

This environmentally friendly design offers the most efficient service and backwashining characteristics available — reducing the amount of water to drain in backwash, while increasing the overall filtration capacity of a system. Click here for more information. |

|

|

| |

| |

|