|

| |

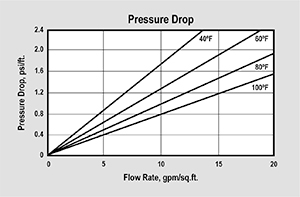

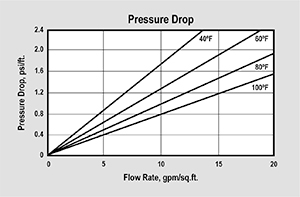

| PRESSURE DROP — The graph above shows the expected pressure loss per foot of bed depth as a function of flow rate at various temperatures. |

| |

|

| |

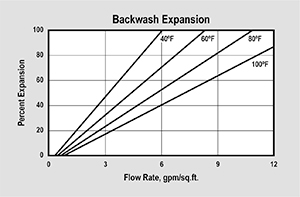

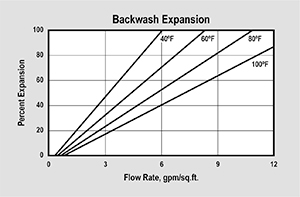

| BACKWASH — The graph above shows the expansion characteristics as a function of flow rate at various temperatures. |

| |

| |

| APPLICATIONS: |

Softening

ProSoft Fine Mesh is an 8% crosslinked cation resin optimized for industrial softening applications. It has higher total capacity than standard crosslinked resins such as ProSoft Gold and has higher operating capacity when relatively large brine doses are used during regeneration. ProSoft Fine Mesh is suitable for hot water applications and for waters that contain modest levels of chlorine. |

| |

|

| |

|

| |

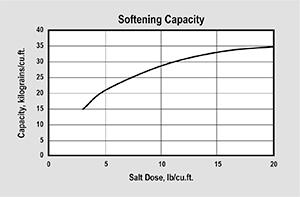

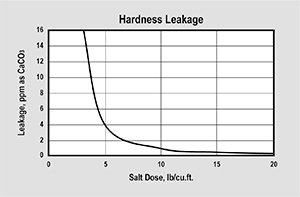

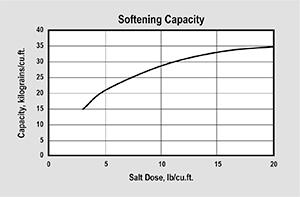

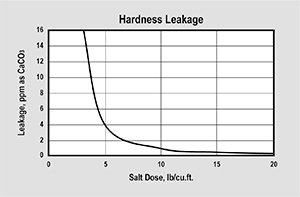

| CAPACITY AND LEAKAGE — Capacity and leakage data are based on 2:1 Ca:Mg ratio, 500 ppm TDS as CaCO3, 0.2% hardness in the salt, and 10% brine concentration applied co-currently through the resin over 30 minutes. No engineering downgrade has been applied. |

| |

Iron Removal

ProSoft Fine Mesh has good capacity for iron removal. Soluble (ferrous) iron is removed by ion exchange, in much the same way as hardness ions are removed. Particulate (ferric) iron is removed by filtration. As a general rule of thumb, to protect against fouling, the iron content in the feedwater should not be more than 1 mg/L Fe per each 17 mg/L of hardness. This ensures an adequate salt dose and frequent regenerations which help prevent fouling. |

| |

| |

| ProSoft™ and ProSelect™ are trademarks of Safe Water Technologies, Inc. |

|

|

| |

Features: |

|

| |

• |

Superior kinetics for high efficiency softeners and use in iron-bearing waters and high TDS solutions |

|

| |

• |

Highly uniform particle size |

|

| |

• |

Low color throw |

|

| |

• |

Superior physical stability provides long life and

low pressure drop |

|

| |

• |

Conforms to paragraph 21CFR173.25 of the Food Additives Regulations of the US FDA |

|

| |

• |

Certified to NSF/ANSI Standard 61 * |

|

|

|

| PART NUMBER |

| Sodium Form |

ER10003 |

|

| |

| PHYSICAL PROPERTIES |

| Polymer Structure |

Styrene/DVB |

| Polymer Type |

Gel |

| Functional Group |

Sulfonic Acid |

| Physical Form |

Spherical beads |

| Resin Color |

Amber |

| Ionic Form (as shipped) |

Sodium |

| Total Capacity |

> 2.0 meq/mL |

| Water Retention |

42 to 49% |

| Screen Size Distribution |

30 to 50 (US mesh) |

| Maximum Fines Content |

30% (< 50 mesh) |

| Minimum Sphericity |

93% |

| Uniformity Coefficient |

1.4 approx. |

| Approx. Ship. Wt. |

50 lb/cu.ft. |

|

| |

| SUGGESTED OPERATING CONDITIONS |

| Maximum Temperature |

280°F (138°C) |

| Minimum Bed Depth |

24 inches |

| Backwash Expansion |

25 to 50% |

| Maximum Pressure Loss |

25 psi |

| Operating pH Range |

0 to 14 |

Regenerant Concentration

Salt Cycle |

10 to 15% NaCl |

| Regenerant Level |

4 to 15 lb/cu.ft. |

| Regenerant Flow Rate |

0.5 to 1.5 gpm/cu.ft. |

| Regenerant Contact Time |

> 20 minutes |

| Displacement Flow Rate |

Same as dilution water |

| Displacement Volume |

10 to 15 gal/cu.ft. |

| Rinse Flow Rate |

Same as service flow |

| Rinse Volume |

35 to 60 gal/cu.ft. |

| Service Flow Rate |

1 to 10 gpm/cu.ft. |

|

| |

| |

|

* CAUTION: DO NOT MIX ION EXCHANGE RESINS WITH STRONG OXIDIZING AGENTS. Nitric acid and other strong oxidizing agents can cause explosive reactions when mixed with organic materials such as ion exchange resins.

|

| |

ADDITIONAL INFORMATION:

SWT Ion Exchange Resin Guide

Cation Resin Selection Chart

Resin Capacity Comparison Chart

|

| |

| |

|

This information has been gathered from standard materials and or test data that is believed to be accurate and reliable. Nothing herein shall be determined to be a warranty or representation expressed or implied with respect to the use of such information or the use of the goods described for any particular purpose alone or in combination with other goods or processes, or that their use does not conflict with existing patent rights. No license is granted to practice any patented invention. It is solely for your consideration, investigation and verification.

|

|