|

| |

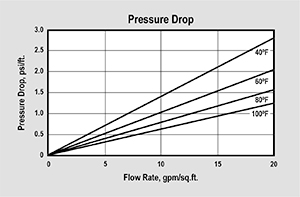

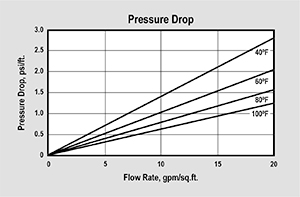

| PRESSURE DROP — The graph above shows the expected pressure loss per foot of bed depth as a function of flow rate at various temperatures. |

| |

|

| |

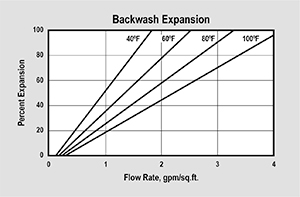

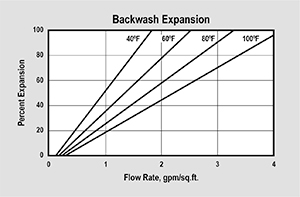

| BACKWASH — The graph above shows the expansion characteristics as a function of flow rate at various temperatures. |

| |

| |

| APPLICATIONS: |

PFAS Removal

ProSelect PFAS can be used for removal of various PFAS compounds, including PFOA and PFOS, from water. Currently, this is a non-regnerable application. Testing has shown it can remove a wide range of other PFAS species in addition to these compounds. Ion exchange offers the benefit of reduced contact times and longer throughputs vs. conventional activated carbon treatment. An understanding of the influent water chemistry is needed for thorough review. Levels of TOC, VOC, and individual PFAS compounds are needed in addition to the basic background water chemistry (chloride, sulfate, alkalinity, etc.). Any other contaminants that may be present are also needed to determine impact on PFAS removal (uranium, perchlorate, chromate, arsenic, etc.). |

| |

Perchlorate Removal

ProSelect PFAS is ideal for single use perchlorate removal applications and is a cost effective method to remove trace levels of perchlorate from water. The perchlorate ion is very strongly attracted to ProSelect PFAS—so much so that regeneration is impractical or impossible. However, in most cases, ER20012-MP loads perchlorate to almost the full capacity of the resin, resulting in very long life and eliminating the need to regenerate and re-use the spent resin. |

| |

| |

| ProSelect™ is a trademark of Safe Water Technologies, Inc. |

|

|

| |

Features: |

|

| |

• |

Highest operating capacity of any perchlorate selective resin |

|

| |

• |

Low sulfate selectivity |

|

| |

• |

Controlled particle size, low pressure drop |

|

| |

• |

Superior physical stability |

|

| |

• |

NSF/ANSI-61 Certified for Material Safety |

|

|

| |

| PART NUMBER |

| Strong Base Anion |

ER20012 |

| Polystyrenic Macroporous |

ER20012-MP |

|

| |

| PHYSICAL PROPERTIES |

Polymer Matrix

ER20012

ER20012-MP |

Styrenic Gel

Styrenic Macroporous |

| Ionic Form |

Chloride |

| Functional Group |

Tributylamine |

| Physical Form |

Spherical beads |

Color

ER20012

ER20012-MP |

Yellow to orange

White to tan |

| Particle Size |

16 to 50 US Mesh

(297 to 1190 μm) |

Minimum Sphericity

ER20012

ER20012-MP |

80%

95% |

| Uniformity Coefficient |

1.6 approx. |

| Reversible Swelling |

Cl to No₃ –5% to –10% |

| Temperature Limit |

250°F (121°C) |

Total Exchange Capacity

ER20012

ER20012-MP |

0.8 meq/mL

0.6 meq/mL * |

Moisture Retention

ER20012

ER20012-MP |

38 to 50%

43 to 58% |

| Regenerability |

Yes ** |

| Approx. Ship. Wt. |

40 to 42 lb/cu.ft.

(641 to 673 g/L) |

| Packaging |

500 ml samples

1 cu.ft. bags

1 cu.ft. boxes

1 cu.ft. drums

7 cu.ft. drums

42 cu.ft. supersacks |

|

| * |

Despite having a lower capacity than ER20012, ER20012-MP has

faster kinetics and can be used at shorter EBCT. |

| ** |

Exception: currently non-regenerable for PFAS removal applications. |

|

| SUGGESTED OPERATING CONDITIONS |

| Maximum Temperature |

170°F (66°C) |

| Minimum Bed Depth |

24 inches |

| Backwash Expansion |

25 to 50% |

| Maximum Pressure Loss |

20 psi |

| Operating pH Range |

4 to 10 SU |

Regenerant Concentration

Salt Cycle |

5 to 10% NaCl |

| Regenerant Level |

>10 lb/cu.ft. |

| Regenerant Flow Rate |

0.25 to 1.0 gpm/cu.ft. |

| Regenerant Contact Time |

> 30 minutes |

| Displacement Flow Rate |

Same as dilution water |

| Displacement Volume |

10 to 15 gal/cu.ft. |

| Rinse Flow Rate |

Same as service flow |

| Rinse Volume |

35 to 60 gal/cu.ft. |

| Service Flow Rate |

1 to 3 gpm/cu.ft. |

|

| |

| |

|

CAUTION: DO NOT MIX ION EXCHANGE RESINS WITH STRONG OXIDIZING AGENTS. Nitric acid and other strong oxidizing agents can cause explosive reactions when mixed with organic materials such as ion exchange resins.

|

| |

ADDITIONAL INFORMATION:

SWT Ion Exchange Resin Guide |

| |

| |

|

This information has been gathered from standard materials and or test data that is believed to be accurate and reliable. Nothing herein shall be determined to be a warranty or representation expressed or implied with respect to the use of such information or the use of the goods described for any particular purpose alone or in combination with other goods or processes, or that their use does not conflict with existing patent rights. No license is granted to practice any patented invention. It is solely for your consideration, investigation and verification.

|

|