DUAL GRADIENT, DOUBLE PLEATED, IMPREGNATED FILTER CARTRIDGES

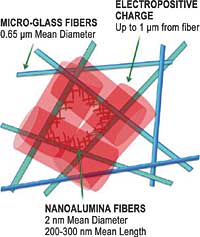

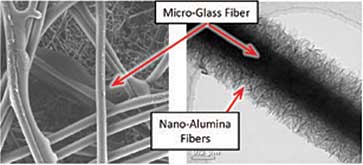

These cartridges are constructed of electropositively charged, dual gradient, double pleated layers for extended life and use. They feature a thermally bonded blend of micro-glass fibers and cellulose, infused with nanoalumina fibers in a nonwoven matrix that creates an electropositively charged depth filter media. When assembled into a pleated cartridge, it offers a unique combination of efficiency, capacity, flow rate, and low pressure drop that allows this nonwoven media to filter like a NF polymeric membrane, at levels unmatched in today's filtration marketplace. In addition, all filter cartridges feature the use of Agion® antimicrobial technology that provides built-in protection by working 24/7 resisting the growth of microbes.

The filters will outperform competitive filtration solutions in all turbidity applications including insoluble scale, ferric iron, bacterial iron slime, colloidal solids, silt, rust, and other particle filtration, resulting in higher water quality and longer life of the filtration system. |

| • |

Primary filtration in lieu of microporous membranes |

| • |

Makeup water (particulate, microbial control) |

| • |

Polishing filters (carbon fines, emulsified oil removal) |

| • |

RO prefiltration (SDI reduction) |

| • |

Process water (turbidity, particulate, colloidal suspensions) |

| • |

Waste water (biologicals, proteins, dyes) |

| • |

Cooling towers & chill water loops (iron removal) |

|