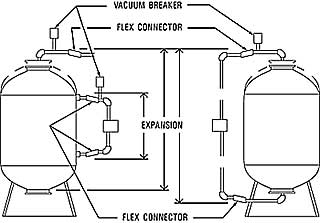

Fiberglass/composite pressure vessels are rated for an internal negative pressure of 5-inches Hg (17 Pa) vacuum below atmospheric. If negative pressure could ever exceed 5-inches Hg (17 Pa), an adequate vacuum breaker must be installed between the pressure vessel inlet and any valves (see illustration right). For enclosed tank applications, the vacuum breaker should be installed at the highest location in the system plumbing.

System connections to the pressure vessel must accomodate vertical expansion between side, top, and bottom openings. Either flexibility in piping or flex connectors, as shown here, are recommended. |