| |

Features: |

|

| |

• |

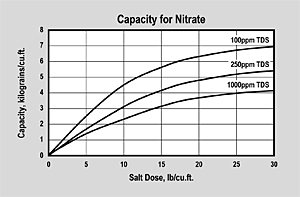

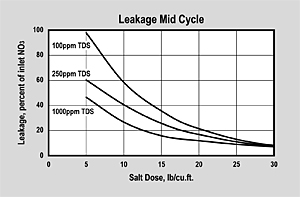

Highest operating capacity of any nitrate selective resin |

|

| |

• |

Highly uniform particle size |

|

| |

• |

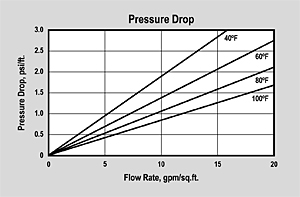

Low pressure drop, superior kinetics |

|

| |

• |

Superior physical stability |

|

| |

• |

Low sulfate selectivity and high operating capacity |

|

| |

• |

Certified to NSF/ANSI/CAN Standard 61 |

|

|

| |

| PART NUMBER |

| Chloride Form |

ER20002 |

|

| |

| PHYSICAL PROPERTIES |

| Polymer Matrix |

Styrenic Macroporous |

| Ionic Form |

Chloride |

| Functional Group |

Triethylamine |

| Physical Form |

Spherical beads |

| Color |

White to tan |

| Particle Size |

16 to 50 US Mesh

(297 to 1190 μm) |

| % < 50 mesh (300 μm) |

< 1% |

| Minimum Sphericity |

95% |

| Uniformity Coefficient |

1.6 |

| Reversible Swelling |

Cl to No₃ –5% to –10% |

| Temperature Limit |

250°F (121°C) |

| Capacity |

1.0 meq/ml |

| Moisture Retention |

46 to 65% |

| Regenerability |

Yes |

| Approx. Ship. Wt. |

40 to 42 lb/cu.ft.

(641 to 673 g/L) |

| Packaging |

500 ml samples

1 cu.ft. bags

1 cu.ft. boxes

1 cu.ft. drums

7 cu.ft. drums

42 cu.ft. supersacks |

|

| |

| SUGGESTED OPERATING CONDITIONS |

Maximum Temperature

Chloride Cycle |

170°F (77°C) |

| Minimum Bed Depth |

24 inches |

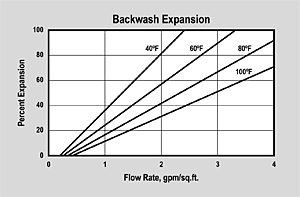

| Backwash Expansion |

25 to 50% |

| Maximum Pressure Loss |

25 psi |

| Operating pH Range |

4 to 10 SU |

Regenerant Concentration

Salt Cycle |

5 to 10% NaCl |

| Regenerant Level |

>10 lb/cu.ft. |

| Regenerant Flow Rate |

0.25 to 1.0 gpm/cu.ft. |

| Regenerant Contact Time |

> 30 minutes |

| Displacement Flow Rate |

Same as dilution water |

| Displacement Volume |

10 to 15 gal/cu.ft. |

| Rinse Flow Rate |

Same as service flow |

| Rinse Volume |

35 to 60 gal/cu.ft. |

Service Flow Rate

Average Flow

Peak Flow |

1 to 4 gpm/cu.ft.

< 10 gpm/cu.ft. |

|

| |

| |

CAUTION: DO NOT MIX ION EXCHANGE RESINS WITH STRONG OXIDIZING AGENTS. Nitric acid and other strong oxidizing agents can cause explosive reactions when mixed with organic materials such as ion exchange resins.

|

| |

ADDITIONAL INFORMATION:

SWT Ion Exchange Resin Guide |

| |

| |

This information has been gathered from standard materials and or test data that is believed to be accurate and reliable. Nothing herein shall be determined to be a warranty or representation expressed or implied with respect to the use of such information or the use of the goods described for any particular purpose alone or in combination with other goods or processes, or that their use does not conflict with existing patent rights. No license is granted to practice any patented invention. It is solely for your consideration, investigation and verification.

|